The electric hoist manufacturing industry is undergoing significant advancements, driven by the need for enhanced safety, efficiency, and sustainability in lifting operations. As businesses across various sectors—construction, manufacturing, and logistics strive to improve productivity, manufacturers are elevating standards by integrating cutting-edge technologies and innovative designs into their electric hoists. One of the most notable developments is the incorporation of smart technology. Modern electric hoists are now equipped with IoT Internet of Things capabilities that allow for real-time monitoring and data collection. This connectivity enables operators to track performance metrics, load weights, and maintenance schedules, thereby minimizing downtime and improving operational efficiency. By harnessing data analytics, companies can predict potential failures before they occur, leading to safer working environments and reduced operational costs. Another key advancement is the emphasis on energy efficiency. Electric hoists traditionally consumed significant amounts of power, contributing to high operational costs and environmental impact.

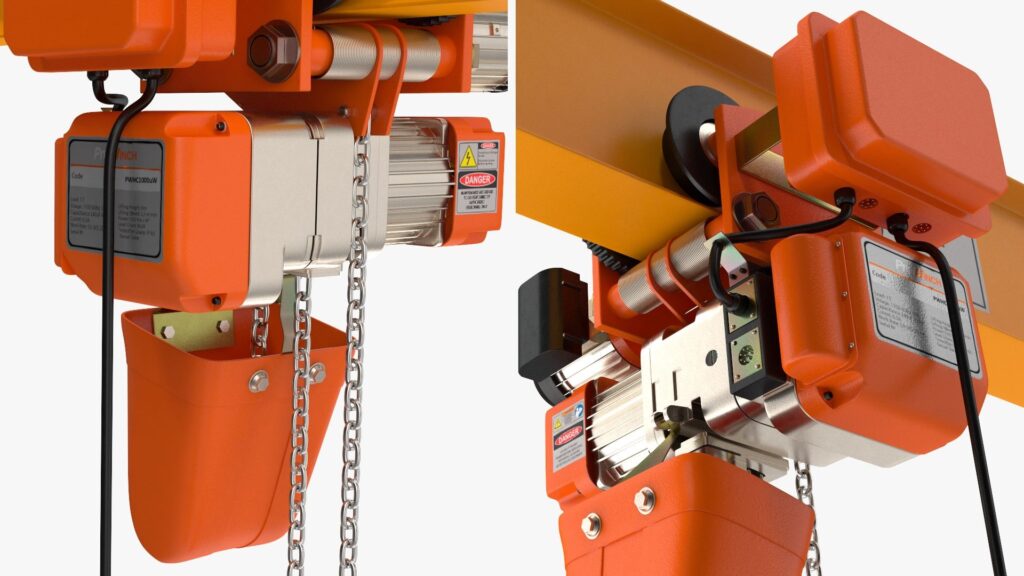

However, manufacturers are increasingly focusing on designing hoists that utilize energy-efficient motors and advanced drive systems. These innovations not only lower energy consumption but also reduce the overall carbon footprint of lifting operations. Additionally, many electric hoists now feature regenerative braking systems, which capture and reuse energy during operation, further enhancing their sustainability. Safety remains a paramount concern in polipasto eléctrico design. New developments include advanced safety features such as overload protection systems, automatic shut-off mechanisms, and enhanced braking systems. These features are designed to prevent accidents and ensure compliance with stringent safety regulations. Furthermore, manufacturers are utilizing lightweight yet durable materials in construction, such as high-strength alloys and composites, which not only improve the strength-to-weight ratio but also facilitate easier handling and installation. Enhanced ergonomics in hoist design are also gaining traction, with user-friendly controls and adjustable features that cater to a diverse range of operators.

In addition to safety and efficiency, customization is becoming increasingly important in electric hoist manufacturing. Manufacturers are recognizing that different industries have unique requirements, leading to a growing trend towards tailored solutions. Whether it is specialized lifting capacities, customized attachments, or specific operational environments, manufacturers are working closely with clients to deliver hoists that meet specific needs. This flexibility not only enhances user satisfaction but also fosters long-term partnerships between manufacturers and their clients.

The rise of electric hoists is also being driven by stricter environmental regulations and the global push towards sustainability. As companies strive to meet these standards, there is an increasing shift from traditional lifting solutions to electric options. This transition not only aligns with corporate social responsibility goals but also demonstrates a commitment to innovative practices that benefit both the business and the environment. In summary, the electric hoist manufacturing industry is experiencing a renaissance characterized by smart technology integration, energy efficiency, enhanced safety features, and increased customization. As these advancements continue to evolve, electric hoists are not just becoming more effective lifting solutions; they are also embodying a commitment to safety, sustainability, and efficiency, setting new standards for the industry as a whole.